Compliances:

Industry Compliances:

CSA C22.2 No. 38

CSA C22.2 No. 51

CSA Approved File # LL 28117

Canadian Electrical Code (CEC)

Other Compliances:

OSHA Acceptable

RoHS Compliant

Product Construction:

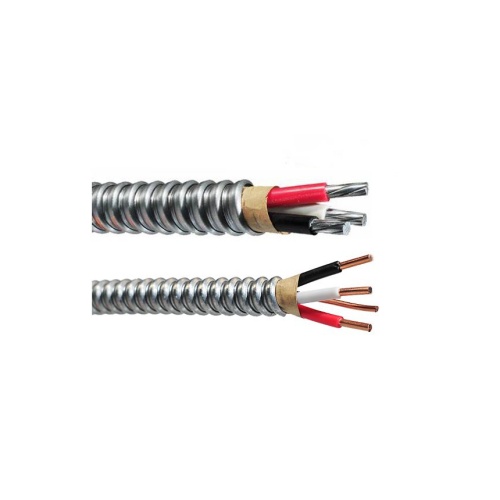

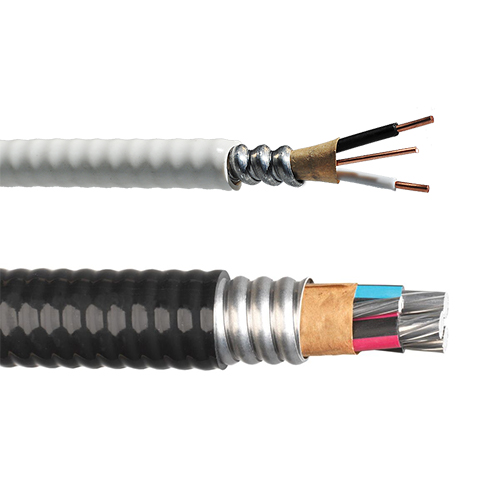

Conductor: Aluminum/Copper compact round concentric lay class “B” stranded

Insulation: Cross-linked Polyethylene (XLPE) Type RW 90

Armour: Aluminum interlocked armou

Features:

Rated 90°C dry locations

UV/sunlight-resistant, moisture-resistant and

flame-retardant insulation

Meets cold and bend impact test at -40°C

Excellent electrical, thermal and physical properties

Excellent crush, oil and chemical resistance

Applications:

For exposed and concealed wiring in dry, locations

For use in ventilated, non-ventilated and ladder-type cable trays in dry locations

Conductor Material: Aluminum/ Copper

Insulation: XLPE

Insulation Colour: Black White

Voltage: 600 V

Maximum operating temperature: 90 °C

Minimum installation temperature: -40 °C

Applications

ACWU 90 cables are primarily intended for exposed and concealed wiring in dry or wet locations and where exposed to the weather. For use in ventilated, non-ventilated, and ladder type cable trays in wet and dry locations; direct earth burial; service entrance above or below ground.

Standards:

CSA Standard C22.2, No. 51 – Armoured Cables

CSA Standard C22.2 No. 174 – Hazardous Locations (HL)

CSA Standard C22.2 No. 0-M91 – General Requirements

CSA Certified File Listing: LL90458, CLASS 581801 – Armoured Cable

CSA Sunlight Resistant

FT-4 – Flame Test Rating

AG-14 – Acid Gas Test Rating

Passes CSA -40°C Cold Bend & -40°C Impact Test

Allows for -25°C Installation Temperature

XLPE Insulation: +90°C Temperature Rating

Aluminum Interlocked Armour

HUADONG CABLE GROUP SINCE 1999

Professional Cables and Wires Manufacturer in China

We can design cables according to your requirement

Verified Manufacturer