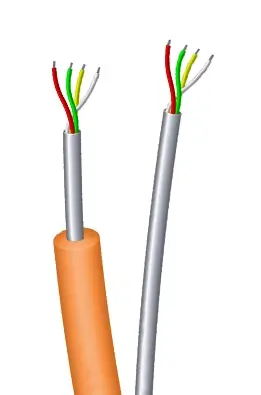

We offer our advanced TEC in both bare and encapsulated variants. Both offer superior reliability and data integrity, and are tailored for different applications.

Construction:

Material: Duplex 2205/ Inconel 825/ Stainless Steel 316L

Outside Diameter: 6.35mm / 0.25”

Seam: Gas Tungsten Arc Weld

Weld Quality: Eddy Inspection

Insulation: FEP

Filler: Polypropylene Grey

Max operating Temperature: 150°C (302°F)

Electrical:

Conductor Size: 8 AWG, 16 AWG

Conductor Type: 8 AWG: 19 Strands of 30 AWG Tinned Copper; 16 AWG: Solid Copper

Diameter: 18 AWG: 1.24mm / 0.049” ; 16 AWG: 1.29mm / 0.051”

Mechanical:

Weight (Bare): 18 AWG:0.103 lbs/ft (0.153 kg/m); 16 AWG: 0.104 lbs/ft (0.155 kg/m)

Applications:

1) Downhole Instrumentation

2) Downhole Accessories

3) Wireline Applications

4) Industrial Power & Communications

When compared to stiff, outdated 1/4” cables there are many beneffts which improve reliability and data integrity.

Metal Jacket:

Material: Incoloy 825/ Stainless Steel 316L

Outside Diameter: 4mm / 0.160”

Wall Thickness: 0.76mm / 0.030”

Seam: Gas Tungsten Arc Weld

Weld Quality: Eddy Inspection

Max operating Temperature: 200°C (392°F)

Conductor Core:

Stranded Bare Copper: 19 Strands of 30 AWG

Size: 18 AWG

Diameter: 1.168mm / 0.046”

Applications:

1) Wellbore-Suspended

2) Surface Read Out

3) Drop Spools

4) Pulled Through Coiled Tubing

5) Attached To Tubing

6) Cemented Behind Casing

7) Real-time data applications

When compared to stiff, outdated 1/4” cables there are many beneffts which improve reliability and data integrity.

Metal Jacket:

Material: Incoloy 825/ Stainless Steel 316L

Outside Diameter: 4mm / 0.160”

Wall Thickness: 0.76mm / 0.030”

Seam: Gas Tungsten Arc Weld

Weld Quality: Eddy Inspection

Insulation:

Material: PFA

Max operating Temperature: 300°C (572°F)

Conductor Core:

Material: Tinned Copper

Size: 4×24 AWG Stranded

Applications:

1) Real-time data applications

2) Permanent downhole monitoring

3) Pressure gauges and strain gauges

4) SAGD and geothermal

5) Electronic slickline

6) Digital slickline

7) Hydrology

HUADONG CABLE GROUP SINCE 1999

Professional Cables and Wires Manufacturer in China

We can design cables according to your requirement

Verified Manufacturer